Long Warranty Condensers For Refrigeration

- GREENINTE

- CHINA

- 30DAYS

- 15SET/MONTH

1.The shell is made of quality steel plate; sprayed plastic surface is anti-corrosive, and its appearance is handsome

2.Coiled pipes are mechanical expanding tubes in staggered arrangement; therefore, copper tubes and fins are combined closely, and ensure good effect of heat exchange

3.This product has passed 2.5 mpa air-tightness test and treatment of system waste

4.It is applicable to such refrigerant as R22,R134a, R404a and R407c,ect.

High Efficient Evaporative Condenser For Refrigeration System:

…………………………………………………

1.Energy-saving and environmental protection, with good use effect

Because of its unique structure, high efficiency of heat exchange performance, low condensation temperature, evaporative condenser has good effect. Therefore, the running power is small, the power consumption is small, its advanced operation principle and the excellent water-pouring matching device reduce the consumption of cooling water, in addition, all materials have good anti-corrosion ability which in adverse it prolongs the service life, the supporting large axial flow fan which has low noise and does not pollute the environment, it is the real energy-saving and environmental protection product. The maintenance is also simple and the running cost is low.

2. Tank

The tank is made up of high-quality galvanized sheet material, with strong anti-corrosion ability, coating protection is conducted in the progressing, all cutting fractures and welding parts are double coated with 95% zinc-rich paint to ensure the service life.

3. High efficiency condensing coil

TZFL series evaporative condenser serpentine coil is made of seamless elliptical tube which is made of high-quality and high-efficiency heat conduction material. The design pressure of the coil is 2.0 Mpa, in the elaborate process, after three times 2.5 Mpa gas-tight test, it is ensured that there is no leakage. The whole coil bracket is treated by zinc dipping at 450 ºC. The thickness of zinc layer is above 0.05 mm. It has excellent anti-corrosion property and can greatly prolong the service life that designed.

4. Large flow pump

Specially use large-flow circulating water pump, the use of high-quality mechanical seals with non-steering restrictions ensure that there is no leakage and a long service life. Equipped with special outdoor motor of high-protection, which has the characteristics of low power, large flow rate, low noise, excellent performance and convenient maintenance and so on.

5. Special axial flow fan

The ventilation system adopts special large-flow axial flow fan. The fan impeller uses aluminum alloy blade, which is light in weight and has strong anti-corrosion ability. The design of impeller structure adopts forward tilt type, with small wind resistance, large air volume, low noise and high efficiency. The supporting motor adopts IP55 self-cooled high-grade protective motor, which runs smoothly and has high efficiency.

6. Large-flow spray nozzle

The evaporative condenser adopts large-flow spray nozzle in the spraying system with the characteristics of large flow rate, even spray and no blockage, it can include tube wall furthest, increasing the moisture vaporization and improving the effect of heat transfer.

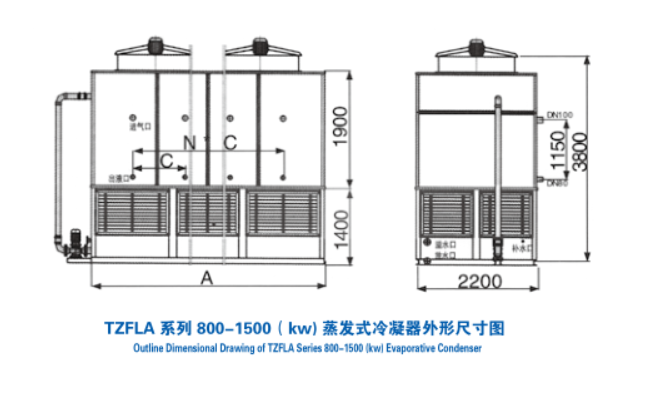

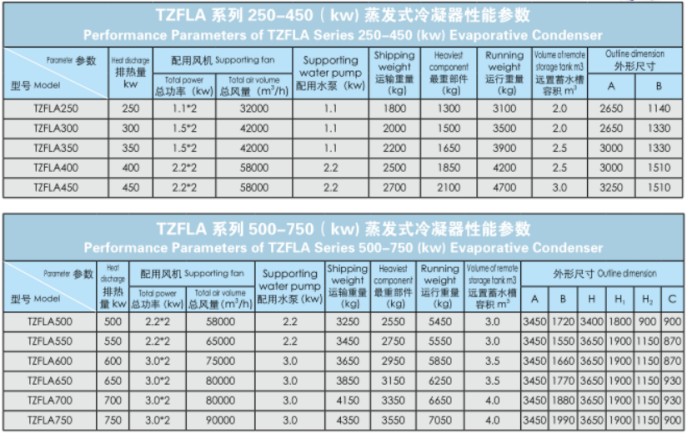

Working Parameter:

Product Features :

Power saving:The company's evaporative cooling adopts a unique design in structure, which reduces the condensation temperature and pressure of the refrigeration system, increases the refrigeration capacity of the compressor,and reduces the power consumption.

Water saving:The dewatering device used in the company's evaporative cooling has a highly efficient dehydration capacity, and the loss of water evaporative and floating is very small, only about 10% of other water-cooled condensers,which greatly saves water resources

Small footprint and easy installation:The evaporative cold integrates condenser, cooling tower,pool, and water pump. lt can be placed on the roof.The installation pipeline is simple, there are no other water system accessories, the installation materials are less, the construction period is shortened, and the installation cost is reduced.

Save maintenance costs: When the machine works in a good environment, the service life can be increased, the trouble-free operation period of the compressor is prolonged, the system reliability is increased, and the maintenance cost is reduced.